The new product design and launch cycles are changing quickly. There are now certain important conditioning factors that must be taken into account when launching a product:

- Commercial targets: you need to be ambitious when calculating your product’s sales, but you must remember that less than 20% of products meet their commercial targets. The commercial targets will not be met in four out of every 5 products designed: fewer units are sold than initially expected or it takes longer to achieve those figures. We should therefore consider different scenarios to minimise the risk.

- Time to market:According to the studies conducted by IBS consultants, a month’s delay in a product launch means a 10% loss in profits on average (depending on the type of product and sector) and a 12 month delay cuts sales by 50% and 90%.

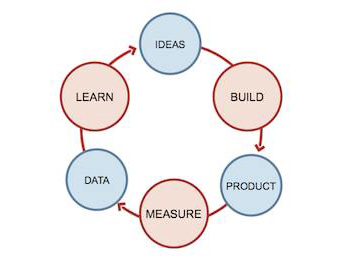

The method proposed by Eric Ries in The Lean Startup is based on an iterative cycle consisting of:

- Developing an idea to transform It into a minimum viable product (MVP)

- Measuring the behaviour of the users

- Analysing the data obtained

- The learning needed to adapt.

There are two clear goals when thinking about applying those methods to designing a Hardware MVP:

- Minimising risk: Using minimum resources to achieve real feedback on the market so as not to spend (or invest) money on a product that will not be sold and thus be able to measure and analyse that feedback to modify our product, launch It (if it is ready) on the market or abandon it.

- Cutting the time to market:This methodology seeks to minimise the resources invested in what the customer does not appreciate and use streamlined development mechanisms to achieve the final product as fast as possible.

When you are embarking on designing and launching a hardware product where there are much longer timelines and greater costs than those for software, you should follow some guidelines:

- Keep it Simple. Place great emphasis on product design. Using brain storming systems is important, but it is equally as important to perform a convergence process which leaves just the essential that your customers are after when purchasing the product. We must try to involve our customers in this first phase. That is important!

- Quick prototypes: Making many and cheap prototypes will help you reach the final solution more quickly and means that any future problems in the development process can be detected at a very early stage. 3D printers for aesthetical assessments, CNC in mechanics and solutions such as Arduino, OpenPicus or BeagleBoard in electronics are essential tools.

- Despite working on prototypes initially, the suppliers and manufacturers should be involved from the earliest stages of the project to avoid problems in production.

- Conducting many field tests with customers will minimise the risk when launching the product and will enable you to pivot and adapt it to your customer’s needs.

- Launch a pre-order campaign on your website using virtual designs and videos of your prototypes in operation. If you manage to raise interest, you can also generate your first earnings. If the production at a sufficiently advanced stage, you can market your first prototypes assembled manually. Once the product is near the market, you can use crowdfunding platforms to kickstart your first sales.

- Once you have the product ready for production, you have just completed 10% or 20% of the journey. You now have to manufacture it and sell it. If the project has been well oriented in the previous steps and you have collected and measured the information correctly, the risk will be minimised. You will be able to better estimate potential sales according to the interest raised and you can channel the investments in production to the sales that you expect